In this article:

We see how to identify the drilling standard for flanges, gaskets & backing rings

We answer: What flange drilling do I need?

Why do I need to choose the correct flange drilling?

Flange Drilling Standards

If you are making and using flanged joints within a pipe system, then you'll need to take into account the flange drill standards (size and position of holes). This is often a missed factor in system design and can have effects that lead to delays in completing the job.

Before ordering or specifying any plastic full face flanges, backing rings or full face gaskets, the required drilling standard should be ascertained. If connecting to existing flanges, the PCD of the existing flange may measured, and using the tables below; the standard can be calculated.

What is the PCD? How do I measure the PCD?

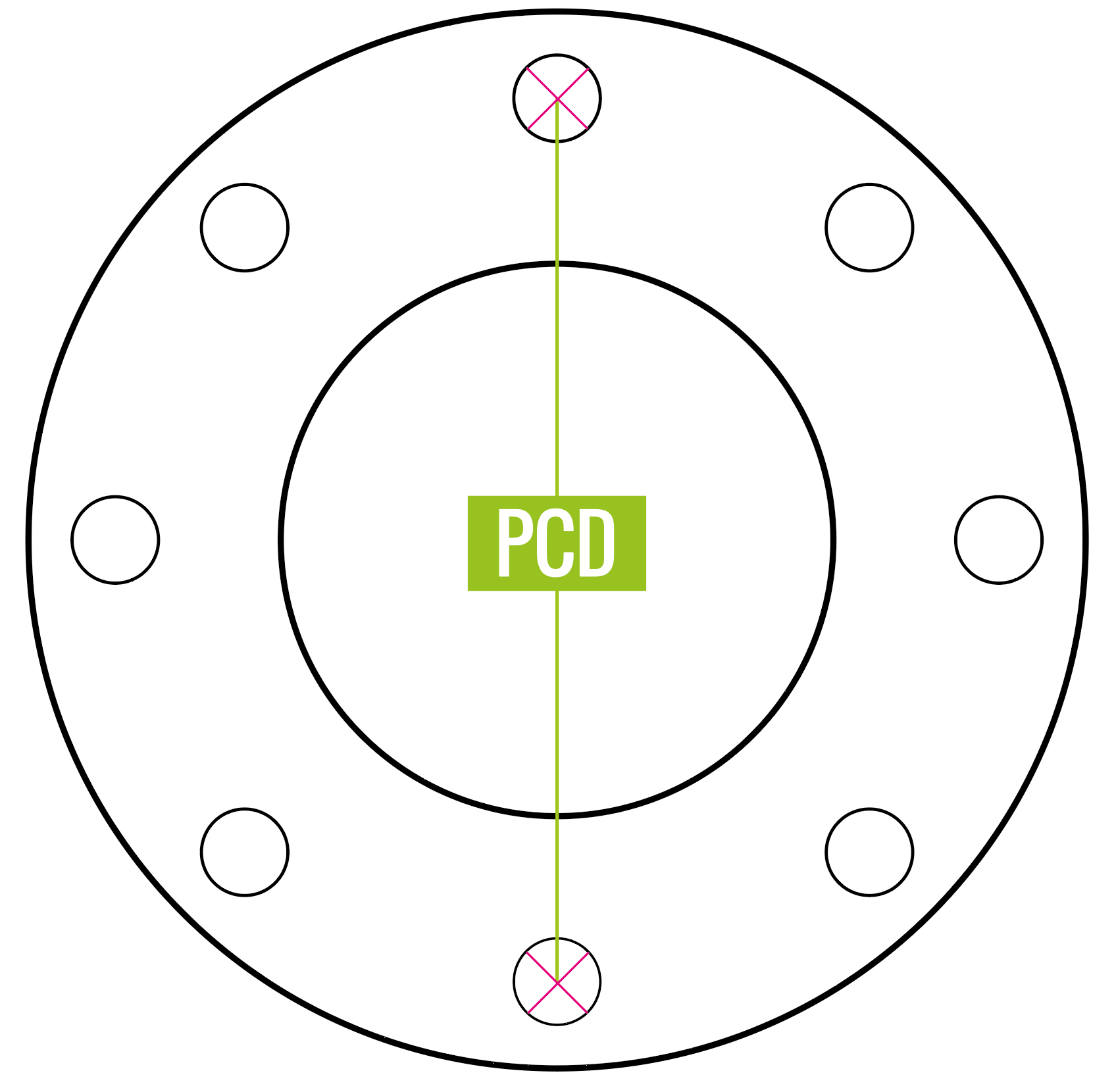

The PCD stands for 'Pitch Circle Diameter', and it is the measurement from the centre of a bolt hole across the centre of the flange to the centre of the opposite bolt hole.

All of the standards for flanges have an even number of holes which makes taking this measurement relatively easy, as there is always an opposite hole to measure to the centre of.

How to Measure.

Using a ruler or tape measure take the measurement in millimetres from the centre point of a hole, across the centre of the flange to the centre point of the opposite hole, as indicated by the green line in the diagram.

All of the standards for flanges have an even number of holes which makes taking this measurement relatively easy, as there is always an opposite hole to measure to the centre of.

Once the PCD has been measured, you can use the following charts to ascertain the drilling standard to ensure compatibility

Flange Drilling Standards:

PN6, PN10 or PN16 are the most common standards today within the UK and throughout Europe.

BS10 (Tables D /E) may be found on older installations and equipment.

ASA 150 is used extensively in North America and may be found in the UK on imported equipment.

PN6, PN10 & PN16 Drilling Standards

PN6

| Pipe Size Inch | Pipe Size Metric | PCD (mm) | Bolt Diameter | No. of Bolt Holes |

|---|---|---|---|---|

| 1/2" | 20 mm | 55 | M10 | 4 |

| 3/4" | 25 mm | 65 | M10 | 4 |

| 1" | 32 mm | 75 | M10 | 4 |

| 1 1/4" | 40 mm | 90 | M12 | 4 |

| 1 1/2" | 50 mm | 100 | M12 | 4 |

| 2" | 63 mm | 110 | M12 | 4 |

| 2 1/2" | 75 mm | 130 | M12 | 4 |

| 3" | 90 mm | 150 | M16 | 4 |

| 4" | 110 mm | 170 | M16 | 4 |

| 5" | 140 mm | 200 | M16 | 8 |

| 6" | 160 mm | 225 | M16 | 8 |

| 8" | 200 mm | 280 | M16 | 8 |

| 10" | 280 mm | 335 | M16 | 12 |

PN10 & PN16 are the most common flange drilling standards in the UK today.

Why are some flanges described as PN10/16?

This is because the flange drillings of many diameters are actually the same between the two tables and therefore the drilling would meet the standards for both tables. This makes the product the same, in terms of hole placement, and suitable for use with either PN10 or PN16 hole specifications.

You'll see the only real difference between the two tables, in terms of hole placement; is the number of holes on the 8" | 200mm flange. But for fitting compatibility, 8 of the 12 holes will align because they share the same PCD and hole diameter.

Why is it that I often see NP10/16 instead of PN10/16?

You may also see the PN10 & PN16 standards referred to as 'NP10' & 'NP16'. These terms are interchangeable and there is no difference between products whether described as PN10/16 or NP10/16.

The 'PN' actually comes from the French, "Pression Nominal", which translates as 'Nominal Pressure'. Although the standards official term would be PN; the term NP is just short for the English translation, which may be preferred by native English speakers.

PN10

| Pipe Size Inch | Pipe Size Metric | PCD (mm) | Bolt Diameter | No. of Bolt Holes |

|---|---|---|---|---|

| 1/2" | 20 mm | 65 | M12 | 4 |

| 3/4" | 25 mm | 75 | M12 | 4 |

| 1" | 32 mm | 85 | M12 | 4 |

| 1 1/4" | 40 mm | 100 | M16 | 4 |

| 1 1/2" | 50 mm | 110 | M16 | 4 |

| 2" | 63 mm | 125 | M16 | 4 |

| 2 1/2" | 75 mm | 145 | M16 | 4 |

| 3" | 90 mm | 160 | M16 | 8 |

| 4" | 110 mm | 180 | M16 | 8 |

| 5" | 140 mm | 210 | M16 | 8 |

| 6" | 160 mm | 240 | M20 | 8 |

| 8" | 200 mm | 295 | M20 | 8 |

| 10" | 280 mm | 350 | M20 | 12 |

PN16

| Pipe Size Inch | Pipe Size Metric | PCD (mm) | Bolt Diameter | No. of Bolt Holes |

|---|---|---|---|---|

| 1/2" | 20 mm | 65 | M12 | 4 |

| 3/4" | 25 mm | 75 | M12 | 4 |

| 1" | 32 mm | 85 | M12 | 4 |

| 1 1/4" | 40 mm | 100 | M16 | 4 |

| 1 1/2" | 50 mm | 110 | M16 | 4 |

| 2" | 63 mm | 125 | M16 | 4 |

| 2 1/2" | 75 mm | 145 | M16 | 4 |

| 3" | 90 mm | 160 | M16 | 8 |

| 4" | 110 mm | 180 | M16 | 8 |

| 5" | 140 mm | 210 | M16 | 8 |

| 6" | 160 mm | 240 | M20 | 8 |

| 8" | 200 mm | 295 | M20 | 12 |

| 10" | 280 mm | 350 | M20 | 12 |

BS10 Table D/E Drilling

| Pipe Size NB | PCD (mm) | Bolt Diameter | No. of Bolt Holes |

|---|---|---|---|

| 1/2" | 67 | M12 | 4 |

| 3/4" | 73 | M12 | 4 |

| 1" | 83 | M12 | 4 |

| 1 1/4" | 87 | M12 | 4 |

| 1 1/2" | 98 | M16 | 4 |

| 2" | 114 | M16 | 4 |

| 2 1/2" | 127 | M16 | 4 |

| 3" | 146 | M16 | 4 |

| 4" | 178 | M16 | 8 (D) / 12 (E) |

| 5" | 210 | M16 | 8 |

| 6" | 235 | M16 | 8 |

| 8" | 292 | M16 | 8 |

| 10" | 406 | M20 | 8 |

BS10 is a British Standard that was the most common flange drill standard throughout the UK before the common adoption of BS4504 PN standards.

Older installations and equipment may have flanges that use this standard for the drilling; in which case, any replacement of components connecting to it will also need to adhere to the BS10 flange drilling standards.

The flange tables D & E of the BS10 standard do differ; but, as we are talking specifically about drilling (hole placement) the tables are basically the same in this regard. This is why we you'll see products and tables condensed in to one table named D/E.

Note: The number of holes specified by the BS10 standard for the 4" designation differs between Table D & Table E. But for fitting compatibility you can fit the 8 hole 'D' to the 12 hole 'E' as 8 of the 12 holes will align, because the hole diameter and PCD are exactly the same.

Links to product pages with BS10 Table D/E Drilling

EPDM Full Face Gaskets | FPM Full Face Gaskets | Backing Rings

ASA 150 (ANSI) Drilling Standards

| Pipe Size Inch | PCD (mm) | Bolt Diameter | No. of Bolt Holes |

|---|---|---|---|

| 1/2" | 60 | M12 | 4 |

| 3/4" | 70 | M12 | 4 |

| 1" | 80 | M12 | 4 |

| 1 1/4" | 90 | M12 | 4 |

| 1 1/2" | 98 | M16 | 4 |

| 2" | 121 | M16 | 4 |

| 2 1/2" | 138 | M16 | 4 |

| 3" | 152 | M16 | 4 |

| 4" | 190 | M16 | 8 |

| 5" | 216 | M20 | 8 |

| 6" | 241 | M20 | 8 |

| 8" | 298 | M20 | 8 |

| 10" | 364 | M24 | 12 |

ASA 150 is a standard used throughout North America and may be found in the UK on imported equipment.

The standard dates back around one hundred years, when ANSI (which was initially the American Engineering Standards Committee, AESC), was in its early years.

In 1920, AESC organized Sectional Committee B16 to develop & unify standards for pipe flanges and fittings. After being approved as an American Tentative Standard, and when the AESC became the American Standards Association (ASA), the flanges and fittings standard was originally released as ASA B16E-1932.

Links to product pages with ASA150 (ANSI) drilling

EPDM Full Face Gaskets | FPM Full Face Gaskets | Backing Rings

Summary:

•

Incorrect selection of drilling standard for flanges, gaskets and backing rings will result in the inability to align bolt holes.

• PN10/16 is the most common drilling standard in the UK today and throughout Europe.

All information provided in this article is intended as a preliminary guide only. These charts and information does not constitute actual advice and

Pipe Warehouse UK is not responsible for any issues arising from the use or reliance on the information contained in this article.