In this article:

We compare the general properties of common thermosplastic pressure pipe materials

We look at: Chemical resistances, temperature ranges and other properties of UPVC, ABS, Polypropylene, HDPE & PVDF as pipework materials.

Each individual pipe material has its own profile of characteristics that affects the material's suitability for an intended application. The most common characteristics that will need to be considered are the material's temperature profile, resistance to aggressive medias, impact resistance and connection methods.

For more detailed technical information for a particular material please choose: UPVC | ABS | PP | HDPE | PVDF

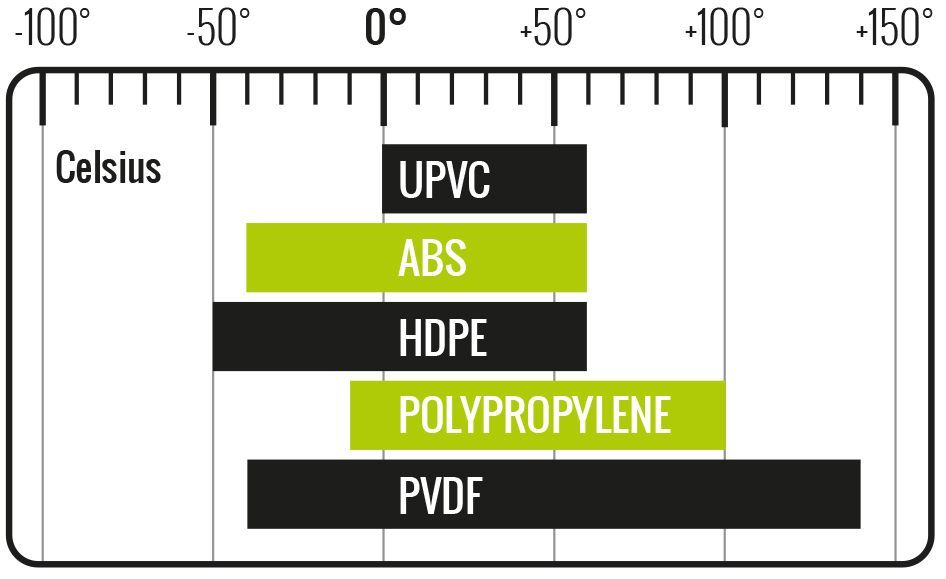

WORKING TEMPERATURE RANGE COMPARISON CHART

MATERIAL CONNECTION METHODS

| Material | Connection Method |

|---|---|

| UPVC | Solvent Cement |

| ABS | Solvent Cement |

| Polypropylene | Fusion |

| HDPE | Fusion |

| PVDF | Fusion |

UPVC MATERIAL PROPERTIES

IN RELATION TO Pipes, VALVES & Fittings

See our range of UPVC pipe and pipe fittings

UPVC Typical Applications

Potable water

Acids & Alkalis

Effluents

Chemical processing

Effluent Treatment

UPVC Key Product Features

Lightweight

Easy to install

Corrosion resistant

Economical

General Material Characteristics OF PVC-U

Unplasticised polyvinyl chloride (PVC-u or UPVC) is one of the most widely used thermoplastic materials for pipe installations.

• Being odourless and tasteless UPVC is suitable for conveying potable water and many food products. PVC-u has excellent chemical resistance.

• The good flow characteristics are the result of the smooth bore and it has good resistance to abrasion.

• UPVC is light in weight and easy to join together, making UPVC a good alternative to more traditional pipe materials.

•PVC-u is resistant to most solutions of acids, alkalis, salts and solvents that can be mixed with water. Additional information regarding chemical resistances of UPVC can be obtained from our chemical resistance chart, our technical staff via telephone on 0161 241 0553 or by email: technical@pipewarehouseuk.com.

RIGID PVC PIPE IS NOT A SUITABLE MATERIAL FOR FOR USE WITH COMPRESSED AIR OR GASES

All rigid PVC is prone to brittle fracture under impact and high energy applications, especially at lower temperatures. Rigid PVC should not be used with compressed media such as air or gases, upon a material failure there is a high risk of injury & death from high velocity airborne shards of shattered material.

MATERIALS

Our PVC-u is stabilised with compounds conforming to the EEC safety levels for Vinyl Chloride Monomer and the WRAS requirements for potable water

COLOUR

Our PVC-u products are recognised by their dark grey colour

RAL 7035

CHEMICAL RESISTANCE

The chemical resistance properties of PVC-u are excellent: it is resistant to most solutions of acids, alkalis and salts and to solvents that can be mixed with water. PVC-u pipe, fittings and valves are not resistant to aromatic and chlorinated hydrocarbons. If piping anything other than water, we would recommend checking the resistance levels against a chemical resistance chart to ensure suitability.

See chemical resistance data for UPVC pipe

Temperature Range

In relation to piping media at pressure, our uPVC pipe range is designed to function for sustained periods within the following temperature range:

0ºC to +60ºC

UPVC DE-RATING CHART

THIS CHART SHOWS THE RELATIONSHIP BETWEEN TEMPERATURE AND PRESSURE FOR UPVC PIPE OF DIFFERENT PRESSURE RATINGS

| CLASS C | CLASS D | CLASS E | PN10 | PN16 | |

|---|---|---|---|---|---|

| TEMPERATURE ºC | BAR (PSI) | BAR (PSI) | BAR (PSI) | BAR | BAR |

| 0 | 9.0 (130) | 12.0 (174) | 15.0 (217) | 10.0 | 16.0 |

| 20 | 9.0 (130) | 12.0 (174) | 15.0 (217) | 10.0 | 16.0 |

| 30 | 8.1 (117) | 10.8 (156) | 13.5 (195) | 8.0 | 12.8 |

| 40 | 6.3 (91) | 8.4 (121) | 10.5 (152) | 6.4 | 10.2 |

| 50 | 4.0 (58) | 5.4 (78) | 6.7 (97) | 4.4 | 7.0 |

| 60 | 1.3 (18) | 1.8 (26) | 2.2 (3.1) | 2.6 | 4.1 |

This chart shows the recommended maximum working pressures of UPVC pipe based on the conveyance of water at different temperatures. Different pipe materials have different material properties, so can handle different temperatures, this chart is specifically relating to UPVC. This chart does not apply when piping any fluid that is any more aggressive than water, the piped media can affect overall performance of the pipe; as always, we recommend speaking to us if you need more information in this regard.

ABS MATERIAL PROPERTIES

IN RELATION TO Pipes, VALVES & Fittings

See our range of ABS pipes & pipe fittings

General Material Characteristics OF ABS

ABS (Acrylonitrile Butadiene Styrene) is highly rated as a thermosplastic pipework system and is used in many applications, such as food and beverage processing as well as water and sewerage treatment and many other industries.

• ABS has good chemical resistance with high impact strength and low moisture absorption.

• ABS is non toxic and conforms to the toxological requirements of the British Plastic Federation, British Indiustrial Biological Research Association code of practice for food usage 45/5. It also fulfills the EEC requirements for plastic materials in contact with foodstuffs.

• ABS piping systems are lightweight, rigid and easy to install using a solvent cement.

You'll notice that we do not show Metric ABS pipe in the chart below or on our site. Metric ABS is only produced by one manufacturer and is comparatively very expensive, so we do not hold general stock of it, however, if you need metric ABS we can facilitate this for you if you contact us by phone.

COLOUR

Our ABS products are recognised by their light grey colour

RAL 7046

CHEMICAL RESISTANCE

ABS pipes, fittings and valves have good resistance to most diluted inorganic acids, salts, animal fats and oils and organic acids. They are not resistant to organic solvents, alcohol, petrol, acetic acid or vegetable oils. Recommendations as to resistance for specific chemicals can be obtained from our technical department on 0161 241 0553.

SEE CHEMICAL RESISTANCE DATA FOR ABS PIPE & FITTINGS

Temperature Range

In relation to piping media at pressure, our ABS pipe, Valves & Fittings range is designed to function for sustained periods within the following temperature range:

-40ºC TO +60ºC

ABS DE-RATING CHART

THIS CHART SHOWS THE RELATIONSHIP BETWEEN TEMPERATURE AND PRESSURE FOR ABS PIPE OF DIFFERENT PRESSURE RATINGS

| CLASS C | CLASS D | CLASS E | |

|---|---|---|---|

| TEMPERATURE ºC | BAR (PSI) | BAR (PSI) | BAR (PSI) |

| -40 to 0 | 9.0 (130) | 12.0 (174) | 15.0 (217) |

| 20 | 9.0 (130) | 12.0 (174) | 15.0 (217) |

| 30 | 8.28 (120) | 11.0 (159) | 13.8 (200) |

| 40 | 7.29 (105) | 9.7 (140) | 12.1 (175) |

| 50 | 5.85 (84) | 7.8 (113) | 9.75 (141) |

| 60 | 4.5 (65) | 6 (87) | 7.5 (108) |

This chart shows the recommended maximum working pressures of ABS pipe based on the conveyance of water at different temperatures. Different pipe materials have different material properties, so can handle different temperatures, this chart is specifically relating to ABS. This chart does not apply when piping any fluid that is any more aggressive than water, the piped media can affect overall performance of the pipe; as always, we recommend speaking to us if you need more information in this regard.

ABS Typical Applications

Chilled Water

Boosted cold water

Potable Water

Low temperature cooling

De-mineralised water

ABS Key Product Features

Lightweight

Easy to install

Wide temperature range

Tough and Durable

Corrosion resistant

HDPE MATERIAL PROPERTIES

IN RELATION TO PIPES, VALVES & FITTINGS

General Material Characteristics of High Density Polyethylene (HDPE)

Polymers which consist of only carbon and hydrogen (Hydrocarbons) are called polyolefins. Polyethylene belongs to this group, making it an environmentally friendly product.

Polyethylene (PE) belongs to the non-polar materials, and because of this, the material does not dissolve in common solvents and, in addition, hardly swells. As a result PE pipes can not be solvent cemented. The appropriate jointing method for this material would be a fusion method.

HDPE GRADES

High molecular PE Grades of Medium to High density have become state of the art for industrial piping installations. The grades are classified in accordance with their internal pressure resistance in PE80 Minimum required strength (MRS) = 8MPa and PE100 Minimum required strength (MRS) = 10MPa

MATERIAL PROPERTIES OF HDPE GRADES (STANDARD VALUES)

| Characteristics | PE80 | PE100 | Units | Test Standard |

|---|---|---|---|---|

| Density | 0.93 | 0.95 | g/cm3 | EN ISO 1183-1 |

| Yield Stress at 23°C | 18 | 25 | N/mm2 | EN ISO 527-1 |

| Tensile E-modulus at 23°C | 700 | 900 | N/mm2 | EN ISO 527-1 |

| Charpy notched impact strength at 23°C | 110/p | 83/p | kJ / m2 | EN ISO 179-1/1eA |

| Charpy notched impact strength at -40°C | 7 | 13 | kJ/ m2 | EN ISO 179-1/1eA |

| Ball indentation hardness (132N) | 37 | 37 | MPa | EN ISO 2039-1 |

| Crystallite melting point | 131 | 130 | °C | DIN 51007 |

| Thermal expansion coefficient | 0.15 to 0.20 | 0.15 to 0.20 | mm/m K | DIN 53752 |

| Heat conductivity at 23°C | 0.43 | 0.38 | W/m K | DIN 52612-1 |

| Water absorption at 23°C | 0.01 - 0.04 | 0.01 - 0.04 | % | EN ISO 62 |

| Limiting Oxygen Index (LOI) | 17.4 | 17.4 | % | ISO 4589-1 |

POLYETHYLENE Chemical Resistance

Due to its non-polar nature as a hydrocarbon of high molecular weight, polyethylene shows a high resistance against chemical attack.

Polyethylene is resistant to: Acids, Alkaline solutions, Solvents, Alcohol & Water

Polyethylene is not resistant to: Oxidising acids, Ketones, Aromatic hydrocarbons and Chlorinated hydrocarbons

For checking resistance to specific chemicals and suitability of HDPE for your application please contact our technical team on 0161 241 0553

ABRASION RESISTANCE OF POLYETHYLENE

Polyethylene has an excellent resistance to abrasions. As a result, PE piping systems are used in numerous applications for conveying solids & slurries. Experience shows that PE offers considerable advantages over metals and most other plastics for applications such as these.

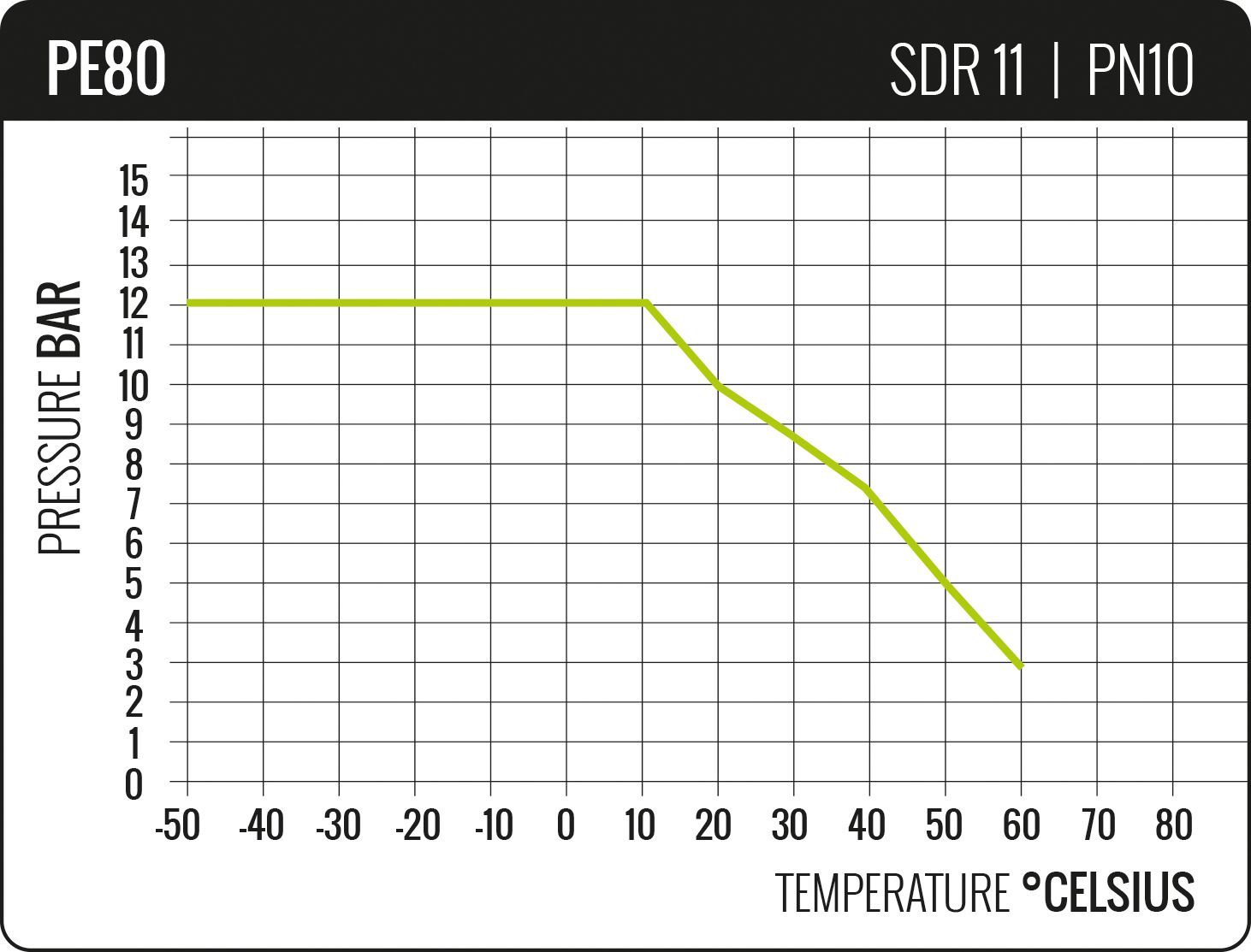

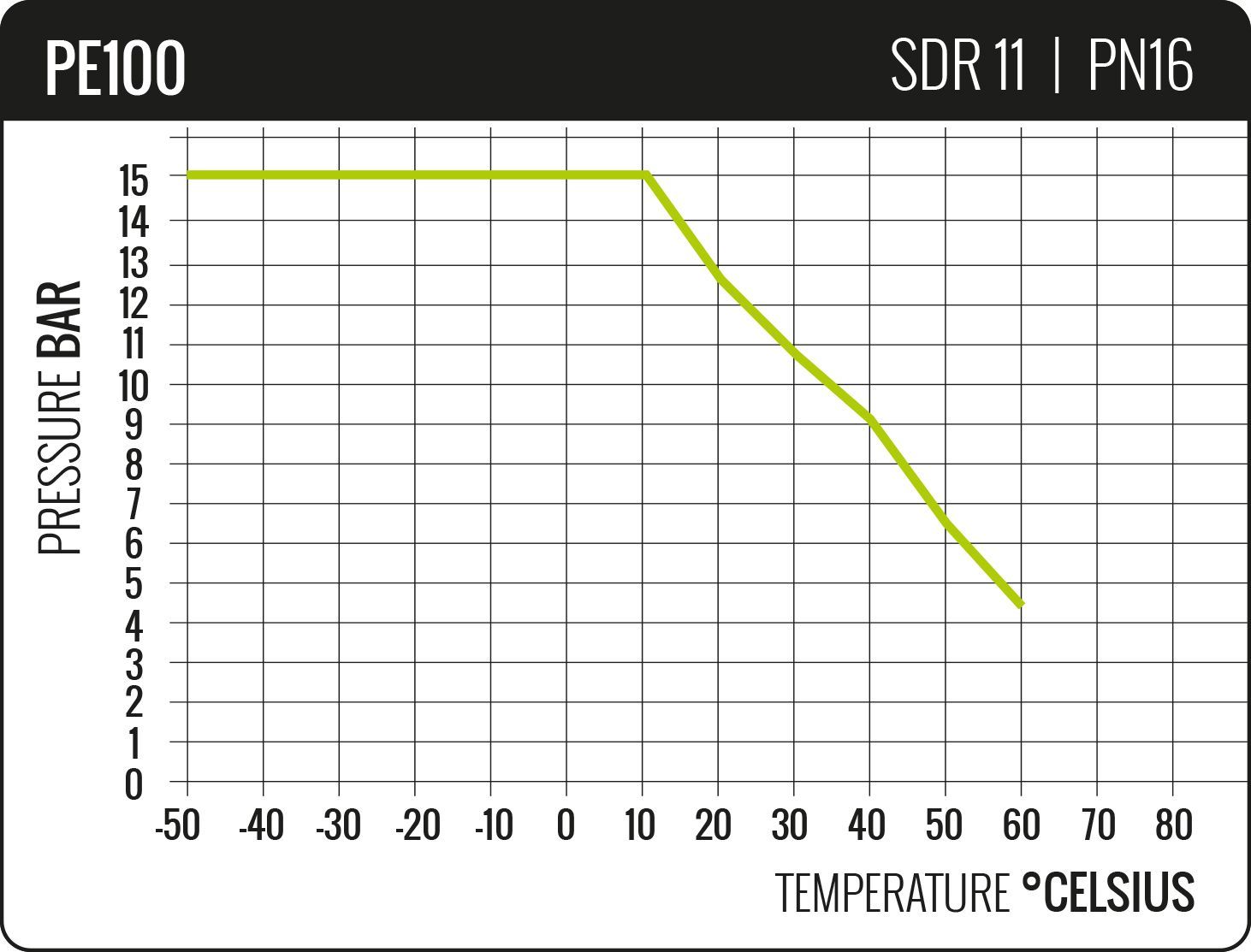

Thermal Properties

Polyethylene pipes can be used at temperatures ranging from -50°C to +60°C.

At higher temperatures, the tensile strength and stiffness are reduced, therefore please consult the pressure temperature diagrams.

The design factor of 1.6 as recommended by the manufacturer has been incorporated into the diagrams. The charts can be used for water similar media, that means, media, which has no derating factor regarding the chemical resistance.

Summary:

•PVCu & ABS materials have different chemical resistance properties - Always check for suitability.

• Both PVCu & ABS are suitable for potable water.

• One main advantage of ABS over PVCu, is that it has a wider temperature range and is capable of handling much lower temperatures for sustained periods.

• ABS has high impact resistance.

• Check your pressure requirements using a Pipe Warehouse UK reference chart or give us a quick call.

All information provided in this article is intended as a preliminary guide only. This article does not constitute actual advice and

Pipe Warehouse UK is not responsible for any issues arising from the use or reliance on the information contained in this article.