TECH TALK

TECHNICAL INFORMATION AND INFORMATIVE HELP ARTICLES

SAFI Products. SAFI Quality

Pipe Warehouse UK offers only quality products from trusted manufacturers, that consistently meet the demands of our industrial clients. We have supplied SAFI products from our business for over 30 Years and here’s why…

SAFI The Company

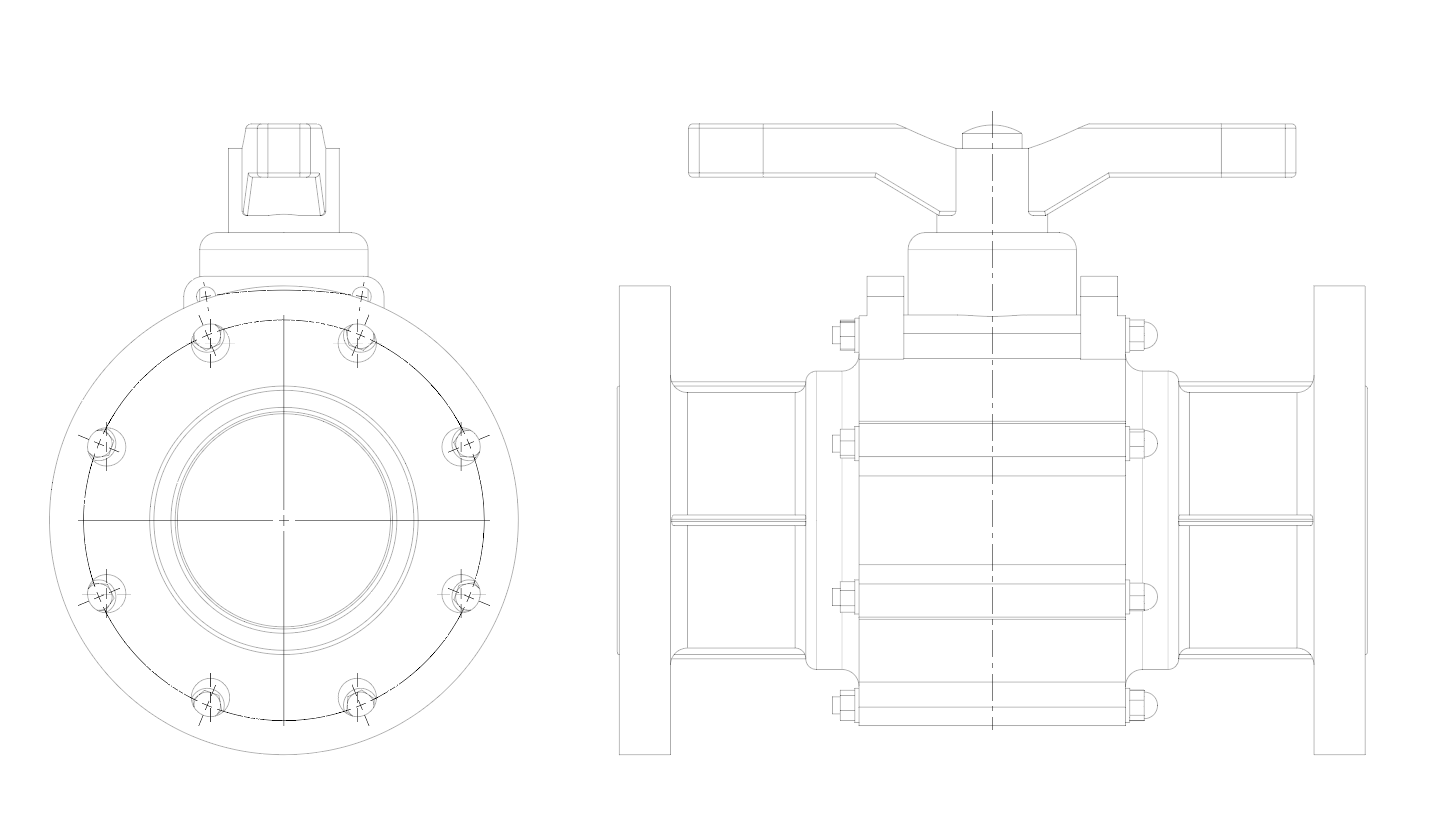

Specialist developers & manufacturers of industrial plastic valves

Founded in 1963 by Jacques MOISON, SAFI specialises in designing and manufacturing a wide range of thermoplastic valves for the most demanding of industry processes.

SAFI service over 70 countries and have become one of the world’s most trusted names in plastic valve solutions. Trusted by blue-chip organisations, across many industries, such as those in:

Environment | Chemical Industry | Transport & Storage | Mining | Surface treatment| Food Industry | Energy | Agriculture | Oil & Gas | Marine

SAFI have a catalogue of over 8000 products that meet the demanding needs of most of the common processes found across industries and they can also tailor valve solutions to specific needs for those even more demanding and less common processes.

SAFI has a long heritage with 60 years of developing & perfecting their craft

SAFI Production

SAFI’s Research & Product Development

SAFi utilise 3D design tools, digital simulation (material resistance, fluid mechanics, etc.) rapid prototyping and 3D printing. SAFI’s internal testing laboratory also allows them to test the different stresses to which the valves are usually subjected. Pressure, temperature, pressure loss, cavitation, etc.

SAFI’s design process is methodical and thorough, it works closely with other departments of the company, to ensure that the product meets the expectations of clients worldwide.

SAFI Engineering

The valves that SAFI manufacture integrate into increasingly complex fluid management and control systems. SAFI teams are trained in systems engineering, in order to respond in a professional capacity to the complex consultations and documentation requirements.

SAFI proficiencies in this field are recognised by the world’s biggest actors in the chemical industry, mining industry and water treatment.

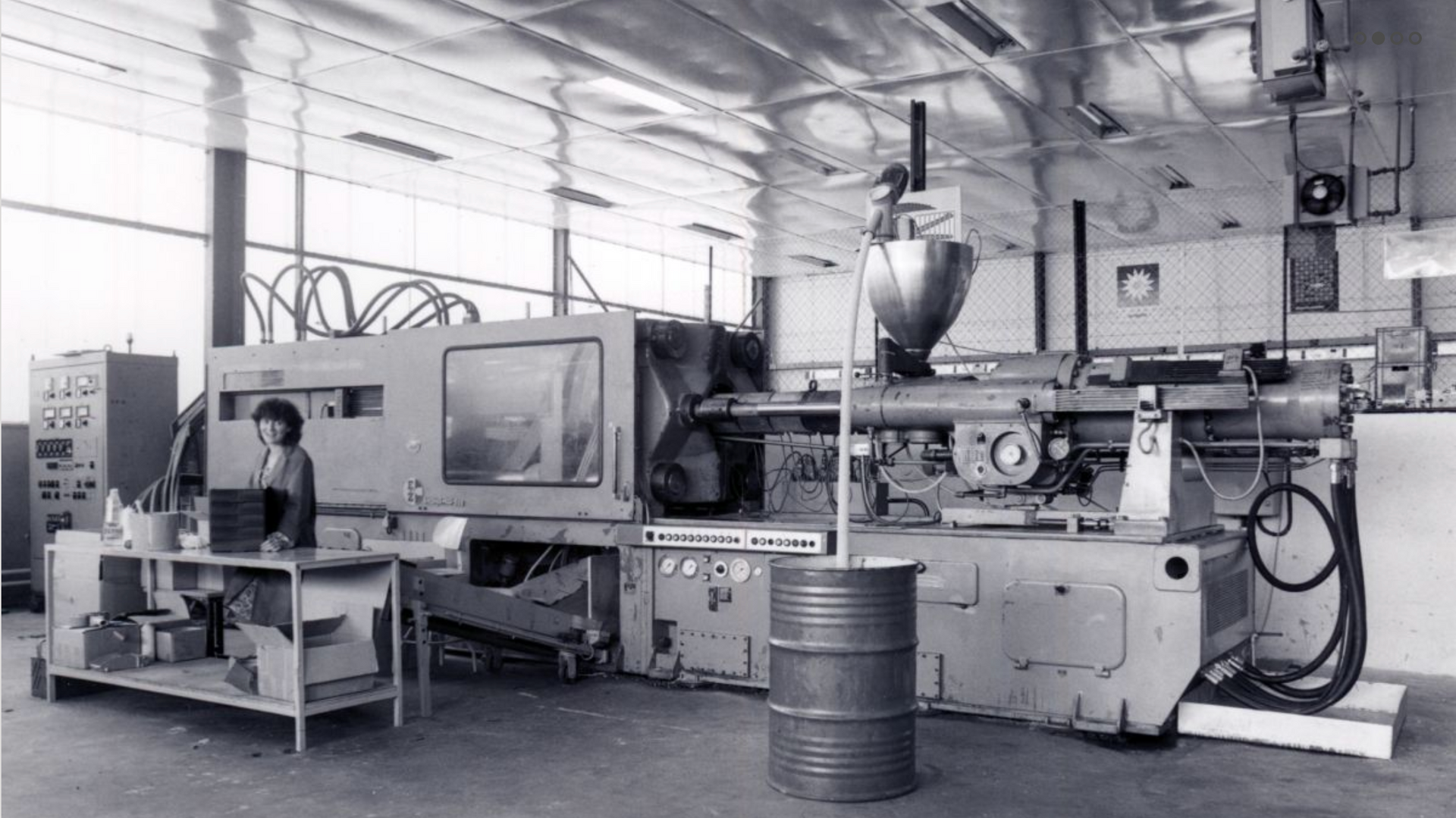

SAFI Manufacturing

All stages of production are done entirely internally:

- Injection of plastic parts thanks to SAFI’s fleet of hydraulic and electric injection moulding machines

- Machining of components

- Assembly

- Tightness test on 100% of valves according to the directives ISO 9393, EN 12266,

From the first design to the finished product, SAFI controls all stages of the conception, development and manufacturing process of its valves.

SAFI Quality

100% of the valves manufactured by SAFI undergo a tightness test.

The majority of the valves that SAFI manufacture are safety products used on hazardous fluids. Quality is a matter of safety and therefore imperative. SAFI has built in over 50 years of its reputation as a manufacturer of robust valves, thanks to the excellence of its designs and the rigor of its processes.

As an ISO 9001 certified company, quality is a value shared by everyone and not just a simple certificate. It is a daily organization well anchored in the group’s culture and structured by applied operating processes.

All of the company is hence working towards a single objective: the satisfaction and safety of their customers.

As a member of directives committees, SAFI carefully apply the directives and standards that are currently in force; in to the design, production and control of plastic valves and their accessories. SAFI have also defined and hold themselves to their own higher standards; which are more restrictive than current directives. For example, they run a tightness test on every single valve

SAFI is a technical leader in the field of industrial thermoplastic valves.

SAFI Products

SAFI have a catalogue of over 8000 products that meet the demanding needs of most of the processes found across multiple industries.

SAFI produce valves in many plastic materials including PVC, ABS & Polypropylene to take advantage of each of the distinct polymer properties and to meet the different demands of various industrial processes.

Glass Reinforced Polyropylene (GRPP)

SAFI have engineered their own Glass Reinforced Polypropylene material; which meets the demands of a wide range of various processes and is therefore popular across industries.

SAFI's GRPP is a composite of polypropylene polymer that also contains 20% borosilicate glass of type "C" chemically resistant and is resistant to temperatures from -10 up to 100°C. The addition of the glass fibre significantly (x2) improves its mechanical resistance to yield stress and impact over standard Polypropylene. Its resistance to UV is improved by addition of carbon pigments and UV stabilisers. All of which increases mean-time between repair/service.

The wide temperature range of the GRPP material has enabled components made from it to be integrated within systems composed of other materials, as the glass reinforced polypropylene has heat resistance beyond the scope of most standard polymers.

As an approved SAFI distributor; Pipe Warehouse UK holds many SAFI products for immediate dispatch and can facilitate orders for other SAFI products too.

Pipe Warehouse UK Inventory of SAFI Products