TECH TALK

TECHNICAL INFORMATION AND INFORMATIVE HELP ARTICLES

Ball Valves - When to Use & How to Choose

Overview of Ball Valves

What is a ball valve?

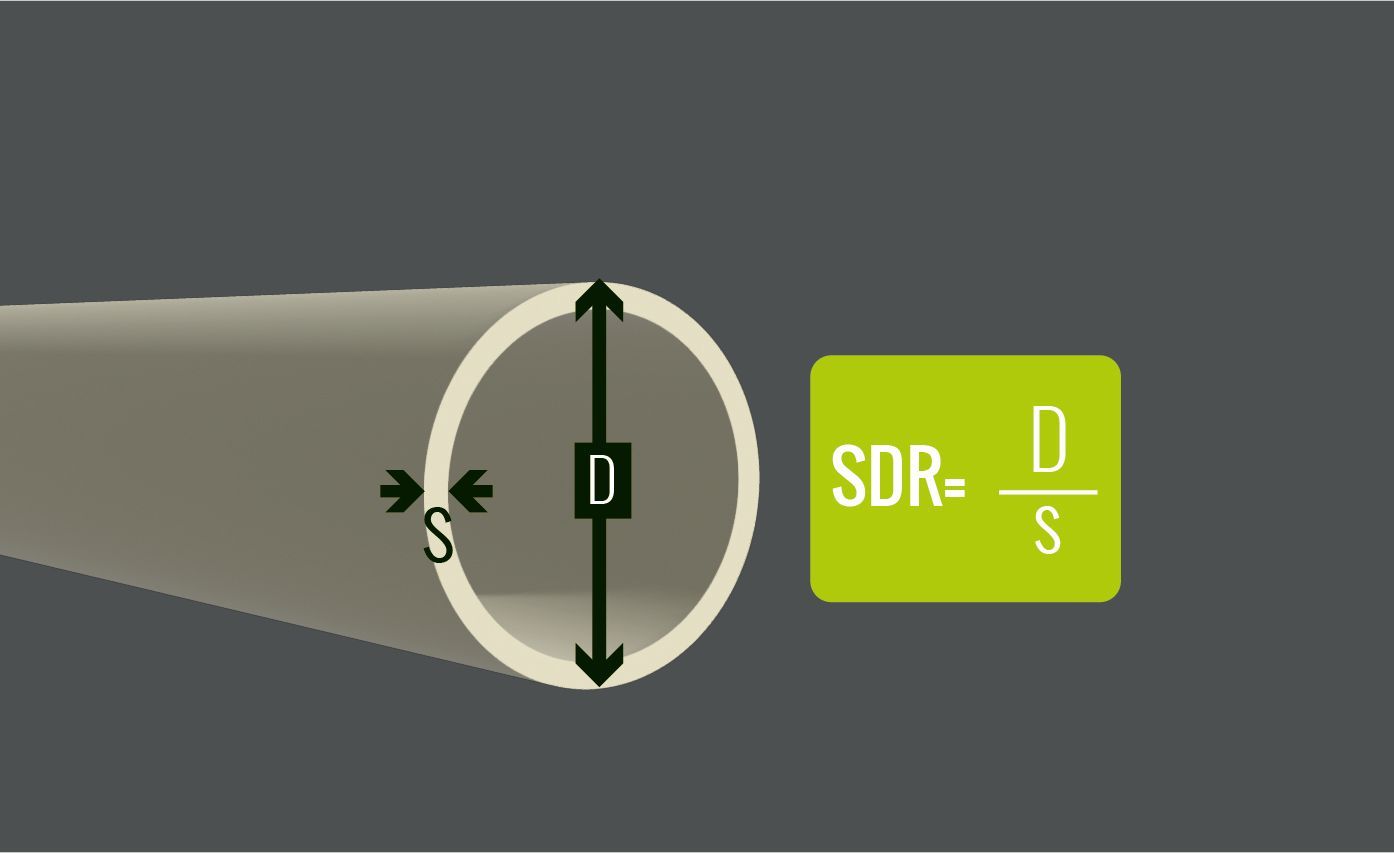

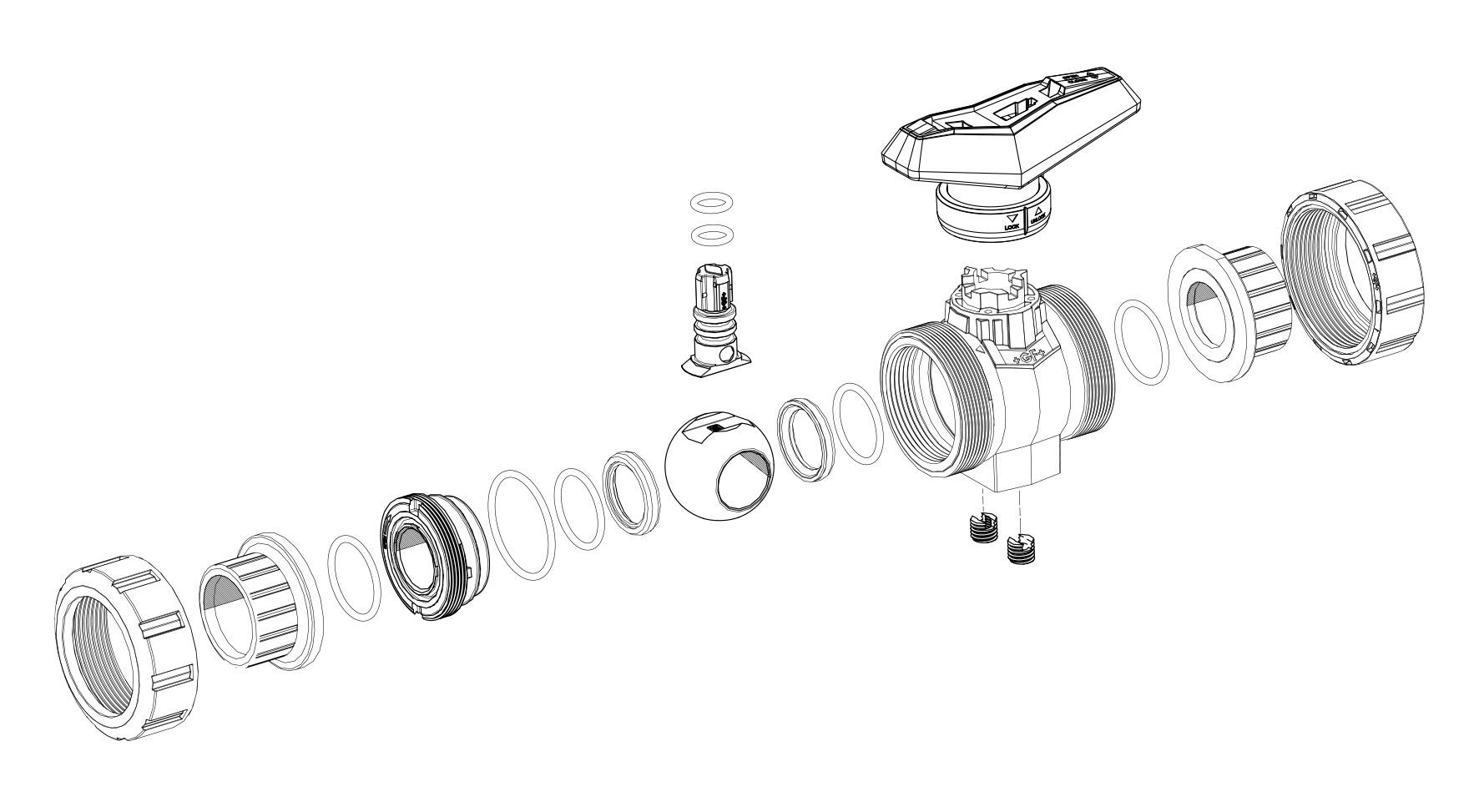

Ball valves are a type of valve that uses a drilled ball to control the flow of liquid or gas in a pipeline. Ball valves have a spherical closure unit that provides on/off control of flow. In the diagram above it shows the component parts, that typically make up a double union ball valve, whilst design may differ between manufacturers, many of these components are typical across most ball valves. The sphere has a bore through the centre. When the valve is in the open position the bore is aligned in the same direction as the pipeline, and fluid can flow through it. When rotated 90°, the bore becomes perpendicular to the flow path, meaning the valve is closed, and media cannot pass through. Ball valves are available in both metal (such as brass) and plastic (such as PVC or ABS) materials. We are primarily concerned in this article with plastic ball valves, as we are specialists in plastic pressure piping.

A ball valve only turns through 90 degrees between fully open and fully closed, which can make it difficult to accurately control flow rates.

Plastic ball valves are typically manufactured between 16mm and 110mm (⅜" to 4" imperial) in size. Valves larger than 110mm / 4" can be too heavy to handle, very difficult to turn manually, and very expensive due to the amount of plastic required.

What is double union?

A double union ball valve has a union nut on both ends of the valve, which holds the connecting end of the valve against a seal on the main body. The union nuts on either side of the valve can be unscrewed and the central body removed for servicing. This enables the main body of the valve to be removed and serviced or replaced very quickly, without cutting the pipe.

When connecting a PVC/ABS double union ball valve, it is important to ensure that no cement enters the body of the valve, or the ball may weld and the valve will not turn. A union end makes threaded connections much easier, as the valve end can be turned independently of the valve.

A single union ball valve has a fixed socket on the discharge side of the valve, and a union on the supply side, whereas a double union ball valve has union ends on both sides. The single union ball valve is usually used on the end of a pipeline, while a double union ball valve is more often used in the middle of a pipeline as the whole valve body can be removed for inspection.

Advantages of ball valves over other types of valve

Compared to gate valves, ball valves are generally more compact and operate at a higher pressure. They also have a full-bore flow without any steps, whereas a gate valve typically has areas where debris can collect. However, a gate valve gives better control of flow rates.

Compared to butterfly valves, ball valves are generally cheaper and have a smaller footprint. Butterfly valves rely on a disc in the middle of the flow which, as well as increasing friction loss, can also catch debris and foul easily. Generally, people prefer ball valves up to 90mm / 3" and butterfly valves above that.

In summary, ball valves are the cheapest option for small, reliable plastic valves for pressure pipe systems. They are the least likely valve type to block or foul and have a full-bore flow when open. Double union ball valves allow for easy servicing, while single union ball valves are typically used on the end of a pipeline.

What to consider when choosing ball valves

Body material:. Generally in plastics; UPVC ball valves are to be used with UPVC pipelines, polypropylene valves are to be used with polypropylene pipelines, and so on. Plastic piping materials have very different working temperature ranges and very different chemical resistance profiles. The decision of which material to use for your pipeline should be one of the primary considerations, so you should already know the material of your pipeline before considering ball valves. The matter of valve body material will have already been decided by your choice of pipeline material as you would want to make sure that chemical resistances and working temperatures of both pipe and valve are the same, or at least similar. See our other articles on material properties if you need to know more.

Seal material: The seals in a ball valve are made from a 'rubber like' materials that can be compressed between rigid separable components, to keep the piped media from leaking out from between the components. There are two main materials used for ball valve seals. The 'standard' seal material in many plastic ball valves is EPDM (Ethylene Propylene Diene Monomer) which is perfectly suitable for water and many other commonly piped media. The second material is FPM (FKM), which has completely different resistance profile to EPDM. FPM is usually found more in industrial applications as aggressive medias can attack the seal material and cause seals to fail; If piping any media other than water, you may want to double check compatibility.

Economy or Industrial

You may see an economy valve with the exact same body material and seal material as an industrial valve from the same brand, so what's the difference? All ball valves are all designed to operate in the same way, but are not of the same material quality and standard of manufacture. Across our product range, you'll notice economy ball valves generally have a blue handle, signifying that they are mainly for use with water and the industrial counterpart is either orange or red handled. That's not to say that the industrial valve can't be used with water and that the blue handled ball valve can't do the job of the industrial. The difference is in the testing, care and the precision used to produce the valve. If an industrial pipeline had to be stopped due to a faulty valve, the downtime could be very costly due to lost manufacture or processing time. In this instance, an industrial ball valve with an orange or red handle would be the option; as whilst we cannot speak for every manufacturer's production method; each individual industrial valve may be checked & pressure tested as it comes off the line, whereas, for example; with the economy valves, samples are checked randomly throughout production and random samples are tested at intervals during production. So basically, the major real difference is the expected reliability. Any guarantees of performance by the manufacturer will be dependant on their application, as such, we would not recommend using economy valves for industrial applications. The other main difference between blue and red handle, is the availability of a wider range of sizes and seal options to cope with the demands from industrial applications. Economy valves will typically only be available in a smaller range of sizes and with no option for FPM seals, as their expected use is less demanding than in industrial applications.

Having said all of this above, it should be recognised that in the wider market there are some cheap, imported ball valves of very poor quality that may be produced with a red or orange handle. If you are looking at industrial valves, then presumably quality is a factor in your purchase decision and it is recommended that you choose a valve from a reputable supplier and from a well-known manufacturer with a high quality of production standards. Pipe Warehouse UK only stock branded ball valves from well known manufacturers with time-proven quality standards that consistently meet rigorous industrial requirements.

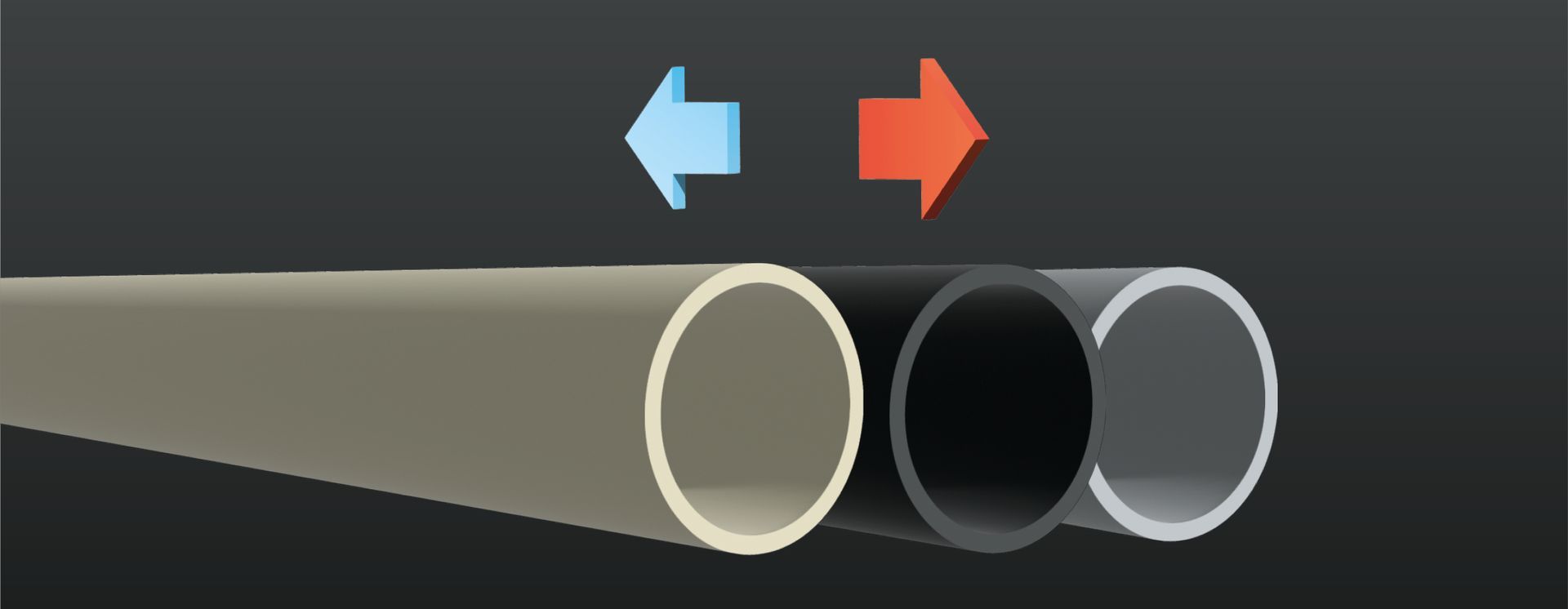

Imperial or Metric

There are two separate pressure piping systems in the UK. Imperial & Metric, they are not interchangeable. It is not a simple case of converting millimetres to inches as one may think. This is a whole subject in itself and will need more explanation, but for the purpose of this article we'll keep it brief. If using metric pipe, only ball valves that are designated as metric will connect directly to metric pipe and the same goes with imperial counterparts. Convertors and adaptors are available to allow the imperial components to connect to metric components, but this may confuse matters when repairs are required in the future. To keep it simple choose a ball valve with the same designation as the rest of your pipe system. For more information on this subject see our article on Imperial vs Metric

Plain or Thread

This refers to the method that you will use to joint the valve within your pipeline.

The ends of a 'Plain' valve, in the case of UPVC & ABS are intended to be jointed into your system using solvent cement, whereas a valve with 'Thread' ends will facilitate the connection of threaded components directly to the valve. The advantages of thread ends is that components of other materials, such as brass, may be incorporated into the pipe system. The use of PTFE tape is recommended when making threaded joints. All valves that are available on pipewarehosueuk.com, unless stated, have BSP standard thread. BSP is the standard of thread that is the most commonly used in the UK today. Other threads may be in use in the UK, but they are far fewer and mostly found on imported components.

More information on BSP thread standard

Size Designation

You should choose a valve of the same size designation as the pipe your are connecting to it, this may sound like it doesn't need to be said; however, there is scope here for confusion, so we would like to try and clarify a few misconceptions and mistakes that even seasoned engineers have made.

Many valves are produced by the manufacturer in both metric & imperial using the same mould for the valve body, therefore the body may be imprinted with both the imperial and metric size designations and if replacing a valve, it may be difficult to ascertain just by looking at a valve body whether you need imperial size or metric as it is the ends that are important for size compatibility.

The size designation of the valve, often shown as 'd' in charts, is either the Outer Diameter of Metric pipe that the valve is intended to fit, which is expressed in millimetres or it is the Nominal Bore of the Imperial pipe that valve is intended to fit, which is expressed in inches and fractions of inches. This should not be confused with DN.

DN (Diametre Nominale) is simply a metric expression of the imperial designation and not the actual outer diameter of metric pipe.

For example; 1¼" expressed decimally is 1.25, this is then multiplied by 25.4 (millimetres in an inch) and the result is 31.75 which is rounded up to the nearest whole number, which gives us a DN of 32. This would

not be compatible with 32mm metric pipe and fittings. At Pipe Warehouse UK, we do not show DN information on our website product pages as we find it tends to confuse matters for most people.

If you need to know more about the way pipe is measured and referenced we recommend this article here Imperial vs Metric