TECH TALK

TECHNICAL INFORMATION AND INFORMATIVE HELP ARTICLES

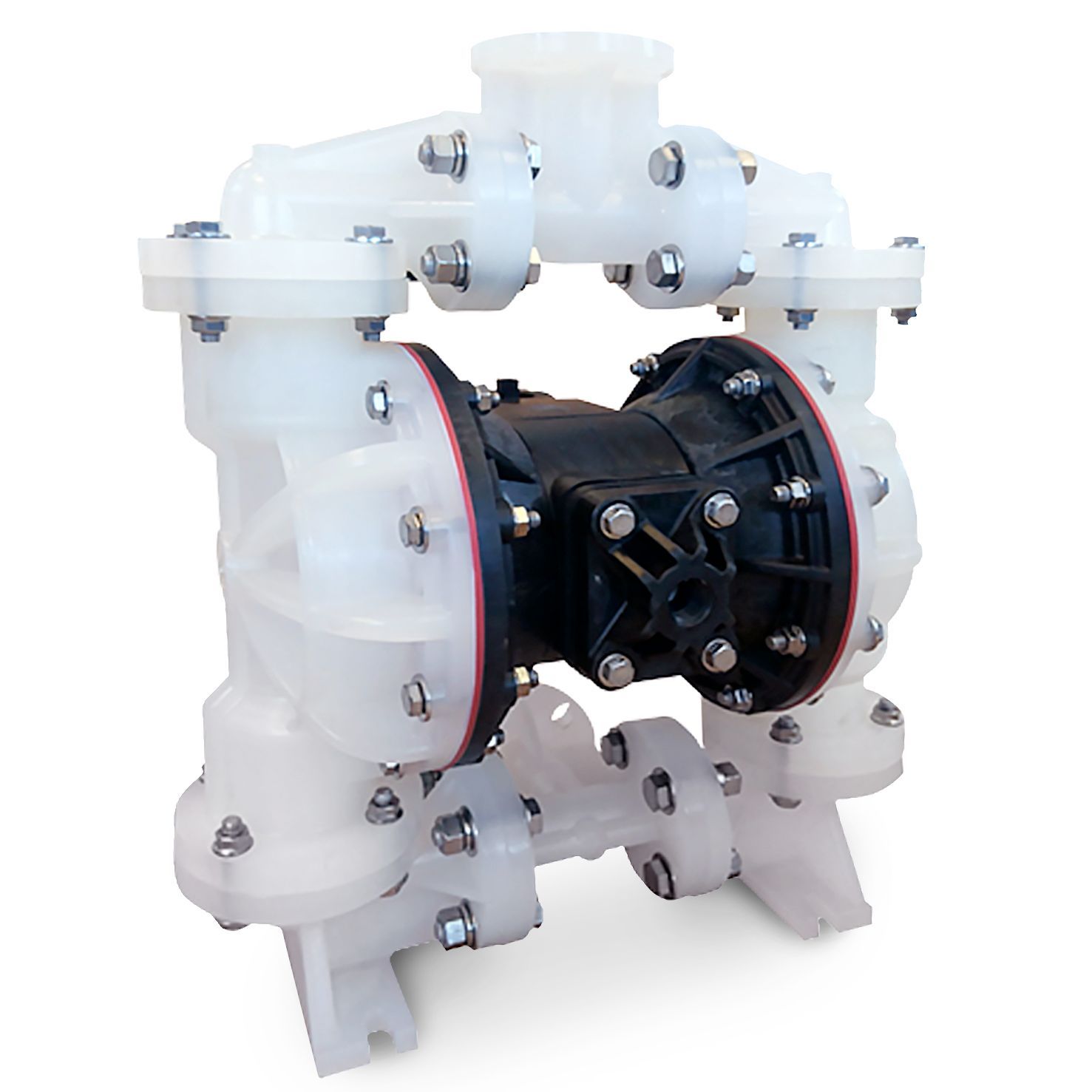

Air Operated Diaphragm Pump Selection Guide

A guide to factors that should be considered when choosing the materials for your Air Operated Diaphragm Pump based on application requirements.

Air Operated Diaphragm Pumps (AODD pumps) are widely used in industrial applications due to their versatility, durability, and ability to handle a variety of fluids, including corrosive and abrasive materials. Selecting the appropriate materials for an AODD pump is crucial to ensuring efficiency, longevity, and compatibility with the pumped media. This guide explores key factors in choosing materials for AODD pumps, including material properties, regulatory considerations, and industry-specific requirements.

Key Factors in Pump Material Selection

Begin by posing a series of targeted questions regarding the specific application for which you need a pump. The responses to these inquiries will clarify your AODD pump requirements and facilitate the selection process. Here are 5 key factors to consider:

1. Chemical Compatibility

- The pump materials must be compatible with ALL of the fluids being transferred.

- Chemical resistance charts help determine suitable materials to prevent corrosion, swelling, or material degradation.

- Incompatible materials can lead to breakdowns, leaks, and costly downtime.

2. Temperature Tolerances

- Industrial environments may involve extreme temperatures that affect material integrity. This is an especially important consideration when you factor in aggressive chemicals, abrasion and high pressure.

- Some materials, like PTFE, withstand high temperatures, while others, like rubber compounds, may degrade faster.

- Temperature fluctuations can lead to expansion and contraction, affecting sealing and efficiency of the pump.

ALWAYS follow the pump manufacturer's temperature range recommendations. The functional temperature range of materials used as components within a pump may be drastically different than the temperature range of materials tested in isolation. Often times manufacturers will supply a range in which the pump will comfortably operate for extended periods without serious detriment to the pump, they may also provide an extended range in which the pump can be operated infrequently and intermittently.

3. Abrasive Nature of Fluids

- Abrasive slurries and suspended solids can wear down pump components.

- Harder materials, such as stainless steel or reinforced thermoplastics, resist erosion better than softer materials.

- Regular inspections and maintenance should be planned for pumps handling abrasive fluids.

- Particle size is also a key deciding factor when considering pump sizes. Suspended solids may block pump components always check maximum sizes. Larger pump designations generally handle larger particle sizes.

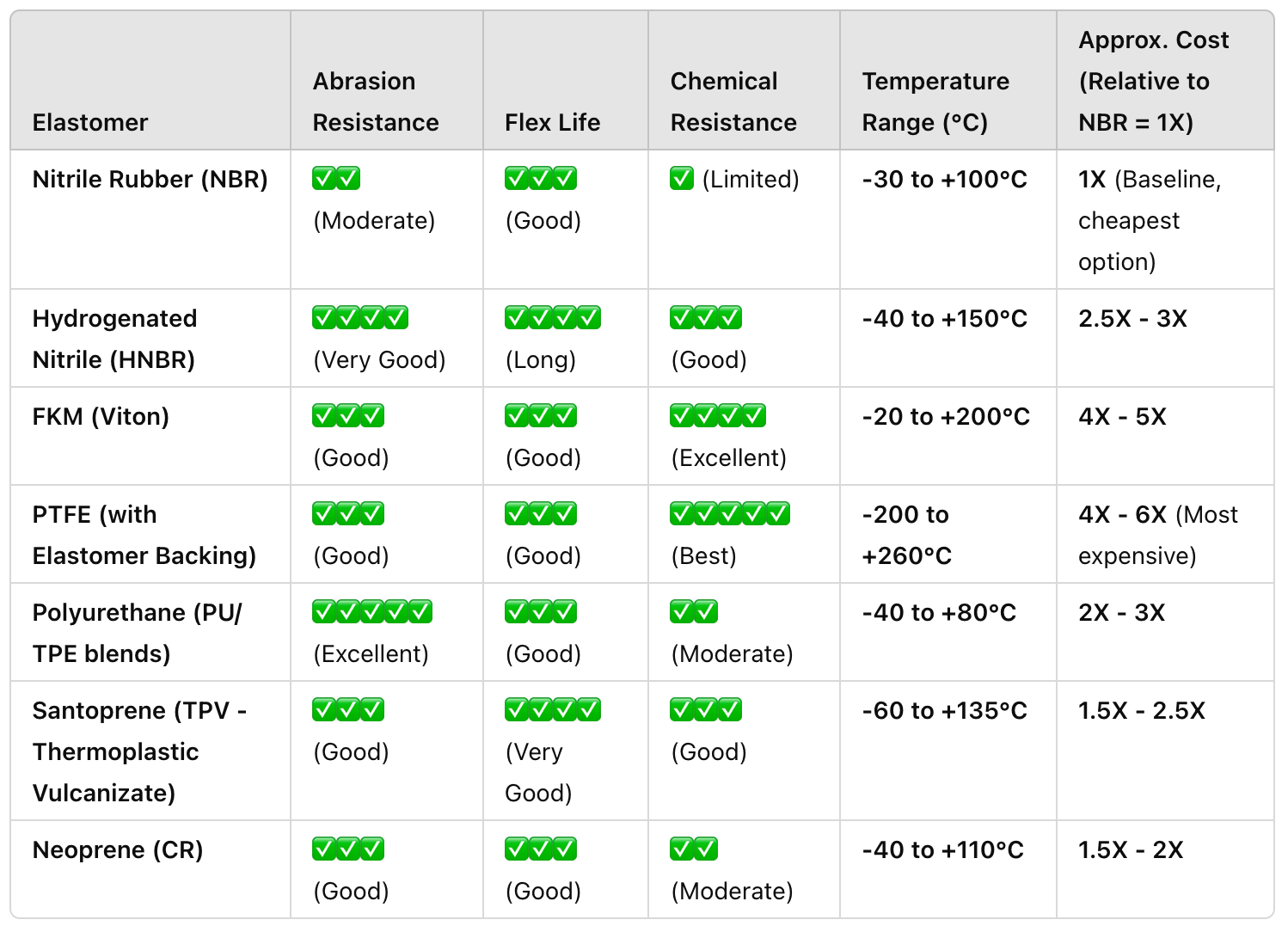

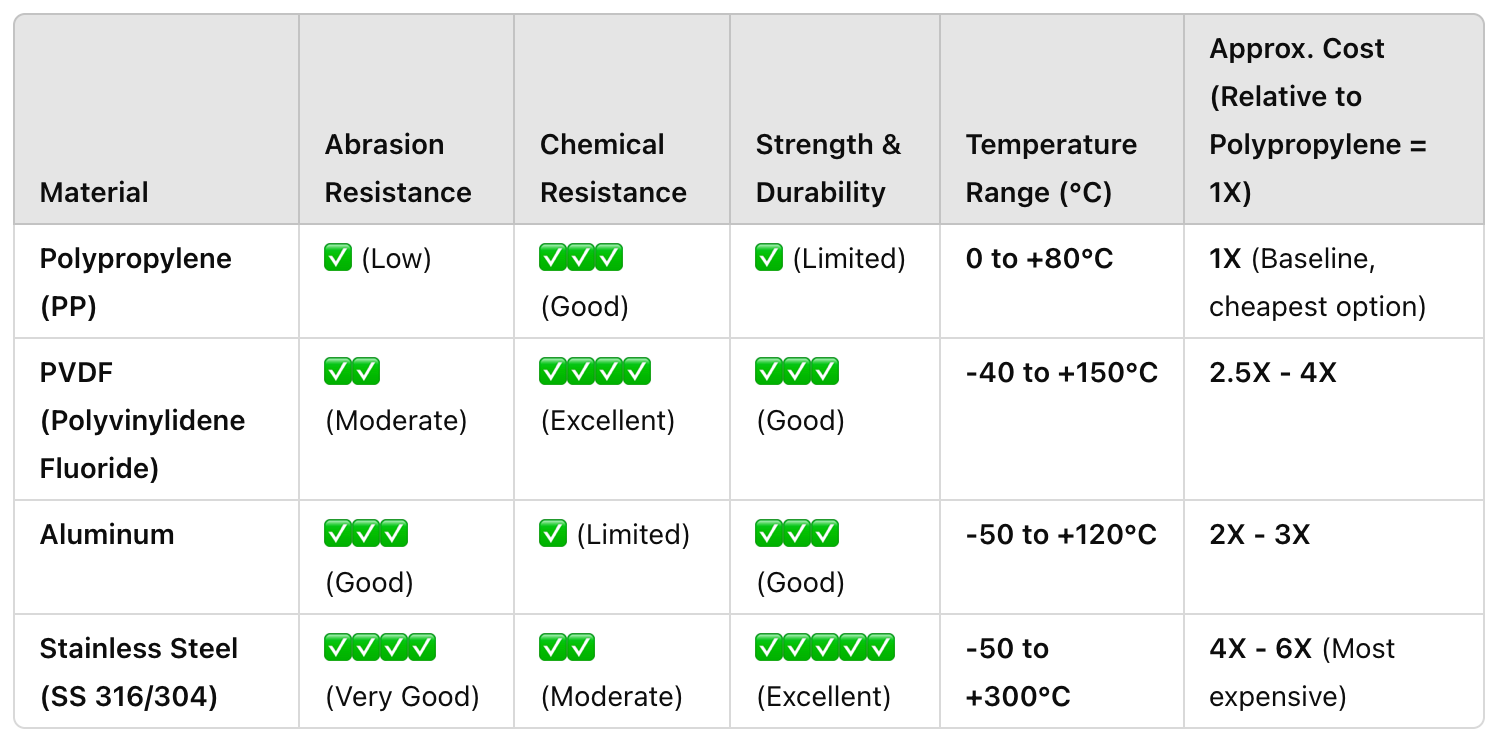

See charts below for a fuller comparison of

Body Materials, and Elastomer Materials.

4. Pressure and Flow Requirements

- The pump’s structural materials must withstand operational pressure and flow rates.

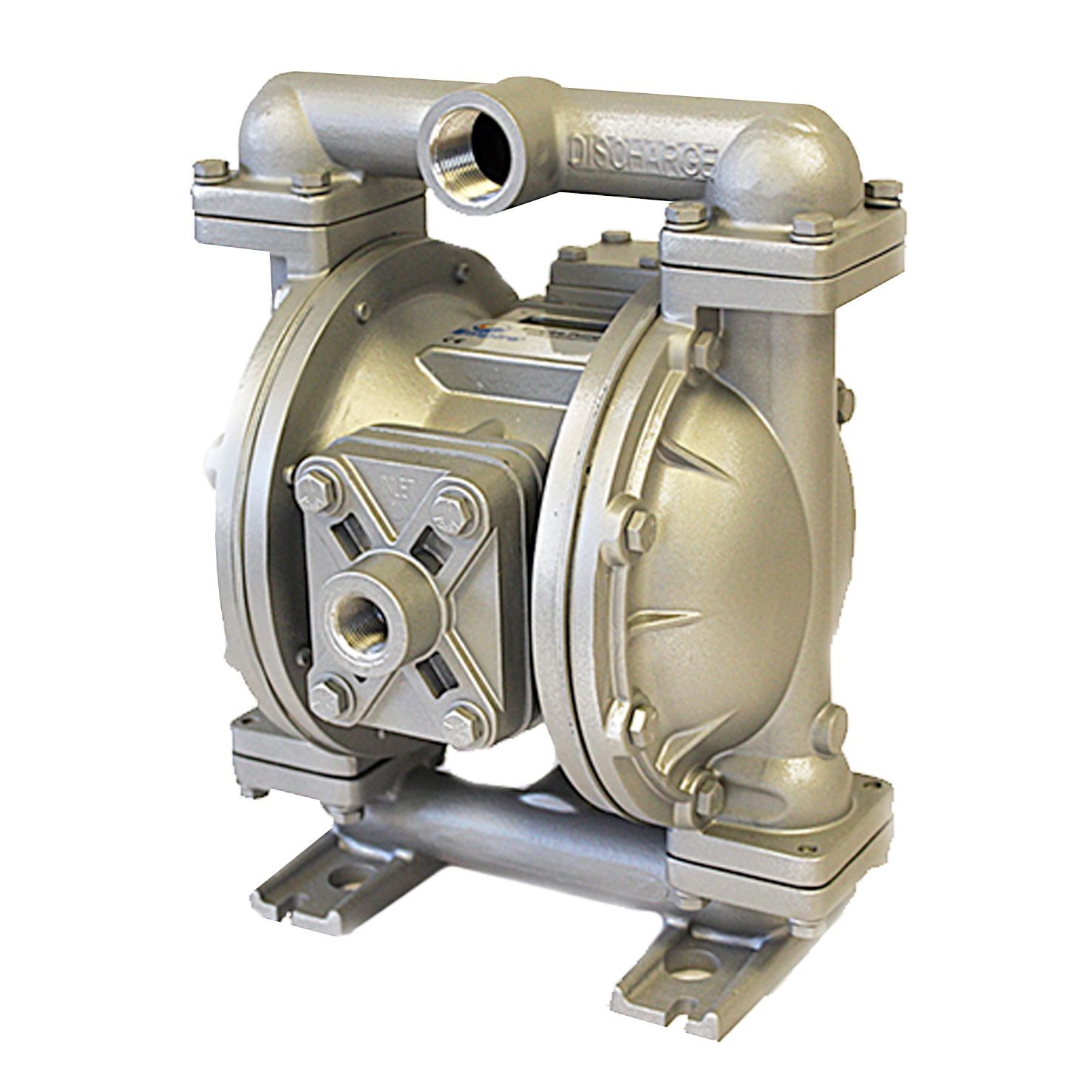

- Metals offer higher strength than plastics but may not be suitable for all chemical applications.

- Overpressurization can lead to material fatigue, making material selection crucial for high-pressure applications.

5. Regulatory Compliance

- Industries such as food, pharmaceuticals, and chemicals require FDA-approved or NSF-compliant materials.

- Material selection should meet industry-specific regulations to ensure safety and legal compliance.

- Additional considerations may include ATEX certification for hazardous environments or USP Class VI compliance for biopharmaceutical applications.

ALWAYS CHECK THAT THE PUMP YOU ARE PURCHASING HAS THE RELEVANT CERTIFICATIONS THAT ARE REQUIRED FOR YOUR APPLICATION.

Pump Material Comparisons

You can use these charts to compare common pump materials to help ascertain the most suitable combination for your purpose.

This is an opportunity to assess overall needs and find the ideal pump material and to balance future costs of downstream maintenance against initial outlay.

CHART INFORMATION CONSIDERATIONS:

Temperature Ranges:

The given ranges are widely considered to be the

isolated material's temperature resistance range. Always check operating temperature ranges supplied by pump manufacturer. If you need to operate at temperatures below freezing, speak to your pump manufacturer.

Chemical Resistances:

The given chemical resistance rating, refers to the

range of chemicals to which the material is considered resistant. A higher rating indicates its

versatility in relation to chemical resistance. Always check resistances to your individual chemicals.

All data given is as a general guide only and does not constitute recommendations.

ELASTOMER MATERIALS COMMONLY USED IN PUMPS

BODY MATERIALS COMMONLY USED FOR PUMPS

Choosing the right material combination

Its all about balance

We have provided these charts to give an overall indication as to the expected comparative performances in relation to each other, this enables you as the purchaser to make a better informed decision in your pump choice, and allowing you to balance budget and performance based on your specific application requirements.

Consider this example; Whilst PTFE material might be rated as A and the superior chemically resistant elastomer for your application, it may also come at a price that is up two and a half times the cost Santoprene; a more budget friendly option that is rated B. So, if slightly more frequent maintenance is acceptable to you, then a budget friendly option may be the right choice. Adversely, if it is very costly for maintenance visits, such as on off-shore installations, then the need for less frequent repair becomes more financially desirable and the superior life of the elastomer will become more important in the purchase decision.

Material Availability

Manufacturers produce pumps of specific material configurations so as to target their range to the common industry requirements. They may limit their range to meet expected demands and some configurations may only be available as a bespoke order with a lead time.

For example:

It is not expected that many applications would demand the necessity of purchasing pumps with very expensive body materials only to have them fitted with the cheapest budget elastomers. Although it is possible to build such a configuration, there will be very little demand for such a configuration and if the need for such a configuration should arise, then it will almost certainly come with an extended lead time.

Some industry configurations

Selecting the right materials depends on the industry and specific application. Below are some general industry-specific AODD pump configurations:

- Chemical Processing: PTFE diaphragms and PVDF housings for resistance to harsh chemicals.

- Food & Beverage: Stainless steel housing with FDA-compliant diaphragms (PTFE, Santoprene) ensures safety and hygiene. Additional polishing may be required for food-grade compliance.

- Oil & Gas: Nitrile diaphragms with aluminum or stainless-steel housing resist fuel and oil degradation. Some applications require explosion-proof certifications.

- Mining & Slurries: Cast iron or stainless steel with ceramic valves withstand abrasive materials.

- Pharmaceuticals: PTFE and FKM (Viton) ensure chemical resistance and compliance with USP Class VI requirements.

- Water Treatment: EPDM diaphragms and polypropylene or PVDF housings provide excellent chemical resistance against chlorinated and acidic fluids.

What now?

Asides from your AODD pump material configuration, there are other essential considerations to factor in to your choice of pump. If you are confident in calculating the required performance then you may want to explore our range of pumps available for immediate purchase. If you would like some professional assistance in ascertaining the right pump for you then drop us an enquiry with some of the specifics of the intended application so we can help identify the correct pump spec for you..

All information provided in this article is intended as a preliminary guide only. The information contained herein does not constitute advice and some subjects briefly mentioned in this article may need further research to be fully understood. Pipe Warehouse UK is not responsible for any issues arising from the use or reliance on the information contained in this article.